Explore Our Wide Range of Expert Fuel Injection Services for Cummins Engines - From Minor Repairs to Overhauls,We Have the Solutions You Need for Optimal Performance and Efficiency!

Assistance Hours

Mon – Fri 7:00am – 5:00pm

Our Services

Mining

Mining equipment operates in harsh conditions, which can affect fuel injection systems. Services for mining fuel injections include repair, cleaning and maintenance, performance upgrades, and engine management system tuning.

Power Generation

Fuel injection systems are critical in power generation equipment, ensuring stable and efficient operation. Services for power generation fuel injections include regular maintenance, cleaning, repair, and performance upgrades to keep the equipment running at peak performance.

Agricultural

Agricultural equipment requires reliable and efficient fuel injection systems to support its demanding work environment. Services for agricultural fuel injections include regular maintenance, cleaning, repairs, and performance upgrades to keep the equipment running smoothly.

Parts

We can quote and supply a wide range of quality parts from our vast network of suppliers at competitive prices. We only offer trusted parts for equipment longevity and performance.

Generators

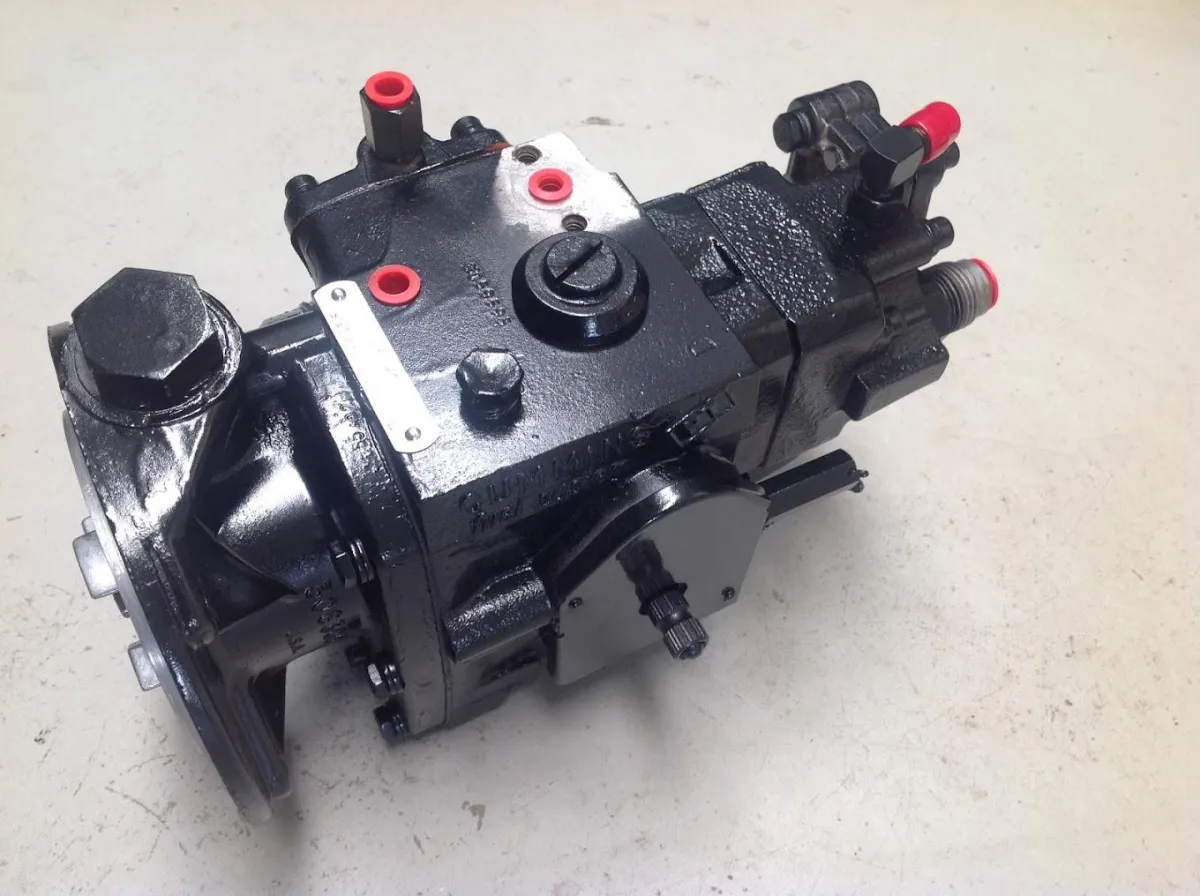

Bead Services has worked with various different generators and specialises in the maintenance, repair, and replacement of the older Cummins PT fuel injection system, ensuring that your generator continues to perform at its best.

Industrial

Industrial fuel injection systems are used in various applications, from heavy machinery to power generators. Services for industrial fuel injections include regular maintenance, repair, and performance enhancements to ensure optimal fuel efficiency and reliable operation.

Transport

Fuel injection services for transport vehicles typically involve repairing fuel injection systems, cleaning and maintaining injectors, upgrading performance, and optimising engine management systems for better fuel efficiency and performance.

Marine

Marine fuel injection systems require special attention due to their exposure to harsh environments and constant use. Services for marine fuel injections include cleaning and maintenance, troubleshooting and repair, and performance upgrades.

OUR TESTIMONIALS

Andrew Towns

★ ★ ★ ★ ★

Great service, no one knows Cummins fuel systems like Dave

John Osborne

★ ★ ★ ★ ★

The best, most experienced, professional CUMMINS diesel fuel injection man in Perth. Possibly Australia. I'm not joking.

Ben Carpenter

★ ★ ★ ★ ★

Very knowledgeable. Fast professional service. Thanks again.

Worked With Us Before?

★ ★ ★ ★ ★

Frequently Asked Questions

What are the benefits of maintaining my PT fuel systems?

Fuel injection systems offer improved fuel efficiency, better emissions control, and increased engine performance. It can also provide a more consistent air/fuel mixture which results in better combustion and more power.

How often should I have my fuel injection system inspected or serviced?

It is recommended to have your fuel injection system overhaul at 385,000km’s, 6000hrs, 3years or as needed. Regular maintenance will help keep your system in good working order and prevent costly repairs and down time.

Can fuel injection systems be repaired or do they need to be replaced?

Yes we do offer an exchange service and have a wide range of fuel pump and injectors available on the shelf ready to go, however, if there is something we do not have in stock we can in most cases make up whatever fuel pump or injectors are needed.

How does the cost of fuel injection services compare to traditional carburetor services?

Fuel injection services tend to cost more upfront compared to traditional carburetor services, but they provide long-term cost savings due to improved fuel efficiency and reduced maintenance costs.

How can I maintain my fuel injection system to ensure optimal performance?

To maintain your fuel injection system, it is recommended to regularly change the air and fuel filters, use high-quality fuel, and have the system inspected and serviced as needed. Staying on top of regular maintenance will help ensure optimal performance and prevent costly repairs.

What are some factors that can affect the performance of my fuel injection system?

Factors such as dirty fuel, worn components, and malfunctioning sensors can all affect the performance of your fuel injection system. Regular maintenance and inspection can help prevent these issues.